In 1933, Ralph C. Coxhead purchased the rights and assets to the Hammond Typewriter Company, which had been renamed Vari-Typer. Between 1933 and 1944, Mr. Coxhead is credited with over 1,300 innovations.

Mr. Coxhead himself only held a handful of patents for the Varityper. Unfortunately, it’s impossible to say which Mr. Coxhead personally created, and which of those were created under his supervision, but his impact is certainly substantial. Here are some of those:

Rubber key caps

It’s surprising what a difference soft rubber caps on typewriter keys makes in the typing experience.

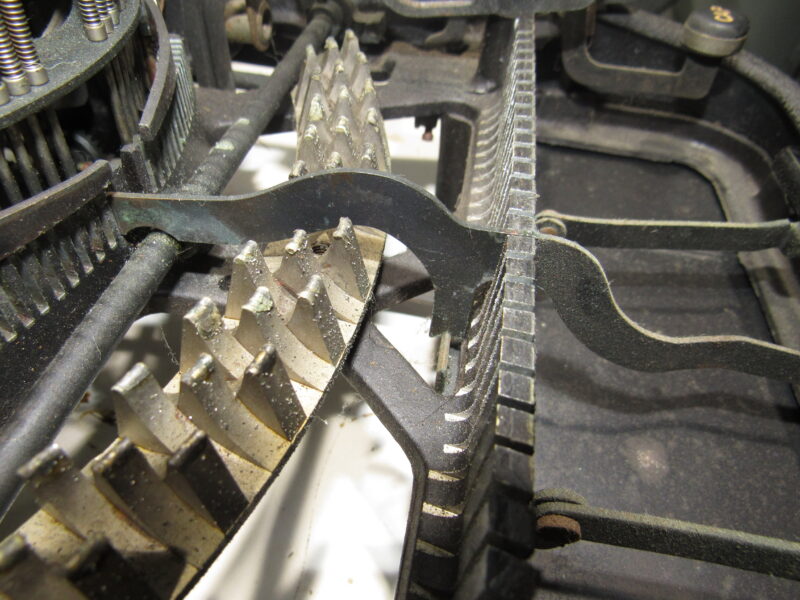

Added stability for key bars

The key bars look almost identical to those from the Hammond era, with the exception of this reinforcement at the pivot point. The key no longer rocks on the edge but rather this metal support.

Steel frame

Swapping out the Hammond’s heavy cast iron frame, and it’s aluminum successor, Coxhead went right to lightweight steel just like everyone else.

Clear paper tube

This one was interesting because of the time period. This particular machine is 1940s, and a clear plastic tube of this size and durability (still holding shape after almost 100 years) was cutting edge manufacturing. Best of all, it allowed the operator to see how much paper was left.

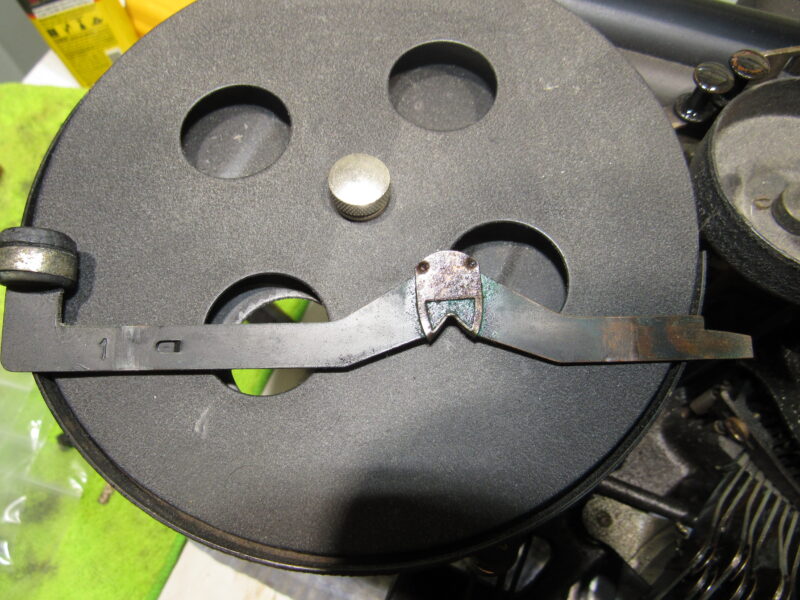

Anvil lift limiter, anvil lift button, and beefed up type select

The anvil shaft has a horizontal pin now that prevents it from being lifted out of the machine. Additionally the type select has continued its trajectory of getting more robust.

Redesigned space key bar

Kind of interesting the space type bar has grown a foot and a pivot spot has been added to the frame for that.

Repetition key

Repetition. Press the button and it simply repeats the hammer blow.

Automatic Ribbon Reversal and Force Necessary to Move the Ribbon

In 1930, not long after Mr. Coxhead and his brother Stuart purchased the Hammond company, an employee named Frank H Trego was creating an automatic ribbon reverse mechanism. When the ribbon got to its end it would trigger a lever that would shift the ribbon gears to begin moving in the opposite direction.

Charles A. Fuchs would improve on this even further in 1933 by changing the energy needed to move the ribbon feed, from one that was generated by the operator pressing a key, and instead when the key was returned to its original position as driven by the mainspring.

Undoubtedly many of the innovations of Coxhead and others were tweaks to the internals of the machine, so not easily explained, but these inventions propelled the company forward considerably.