The Hammond Anvil and Shuttle was a remarkable leap forward for the company, replacing its entire line of 1 and 1a machines. The innovation of its shuttle system – which often broke – simplified shuttle design, reduced cost, and added robustness to its design. It’s distinctive feature is a metal ring in the center, sitting up just above the machine, and surrounded by a circular plane.

Sometimes confused as a No. 1 or No. 2, the Anvil and Shuttle (A&S) was a limited run produced between 1893 or 1894-95. The serial numbers are between 20,000 and 26,000. James Hammond often stopped manufacturing to implement new ideas, rather than wait to debut innovations at one time.

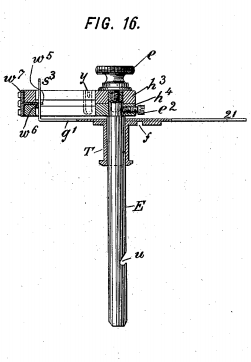

The A&S used a single typing element in the shape of an arc, which moved around a metal ring, powered by a type select arm.

Before, the shuttle was split and had to independent wings that would swing into place for printing. The A&S system did away with that with a single ring it called the anvil.

A type element called the shuttle, made of hardened rubber had a thin metal spine running alongside its back. This metal spine fit into the gap created by the split anvil. The two were then lowered into the machine and aligned with the type select.

The type select has a vertical arm that fitting into a hole in the center of the shuttle. When a key is pressed it rotates this type select which in turns moves the shuttle along the anvil ring.

The crown of the machine was changed to get rid of the vertical portion. The new anvil sat above the machine rather than inside, and it all rode on a slightly wider frame.

Other changes were cosmetic such as cheaper to produce celluloid keys. Everything pretty much stayed the same. The A&S would only last a few years ending production around 1898 when it was replaced by the No. 2.