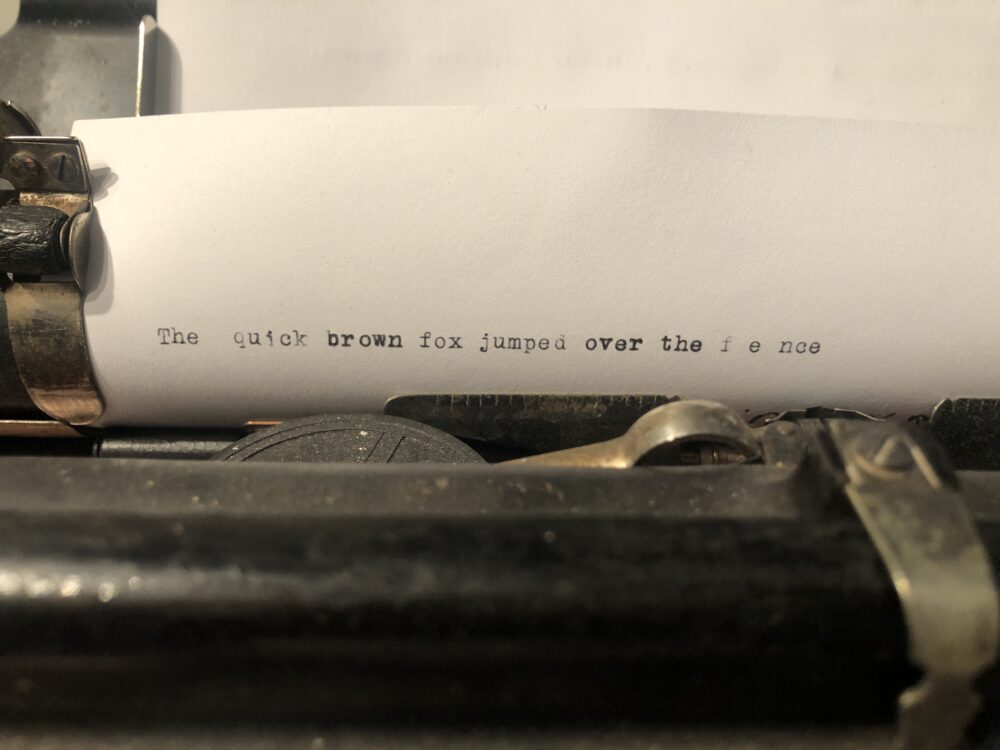

A key feature of the Hammond typewriter is that it strives to provide the same visual impression for each character. It accomplished this through a spring-action mechanism that got its energy from a mainspring, not the fingers of the typist.

In modern, non-electric typewriters the impression of the character is dependent upon the physical force generated by the operator pressing the key.

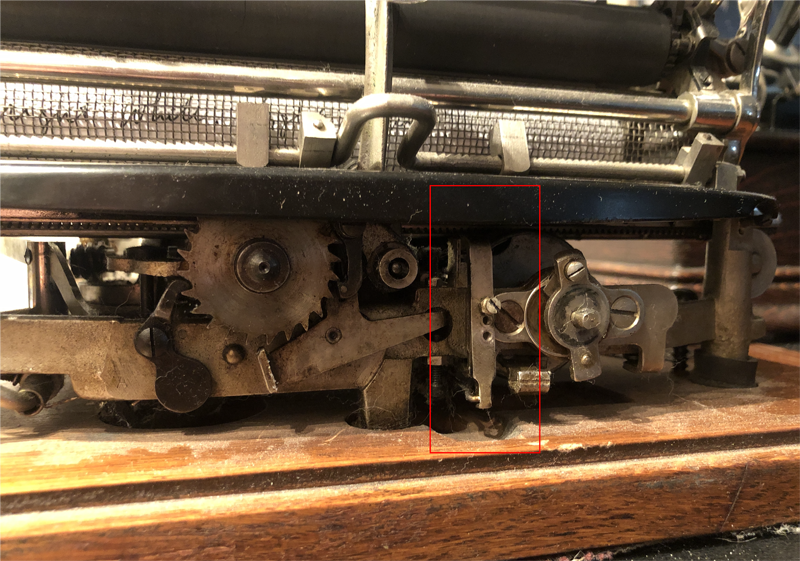

In the Hammond, by disconnecting the typist from the typing mechanism, it does not matter the force used to press the keys, the impression and force of impact of the hammer will always be the same. The force of the impact is regulated on some No 2, No. 12 and later machines, by an adjustable clamp on the rear of the machine.

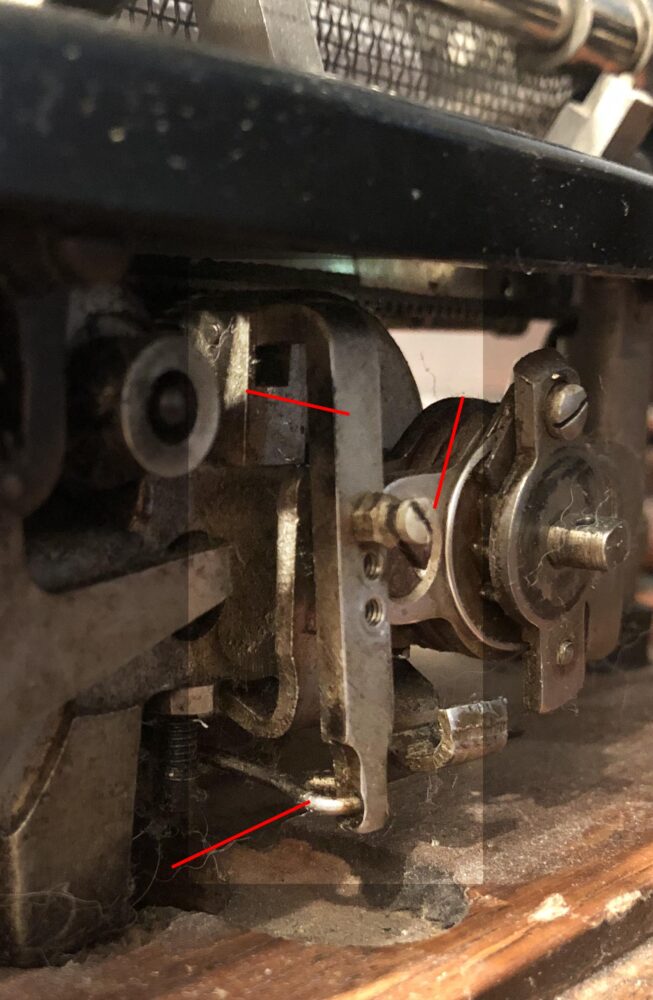

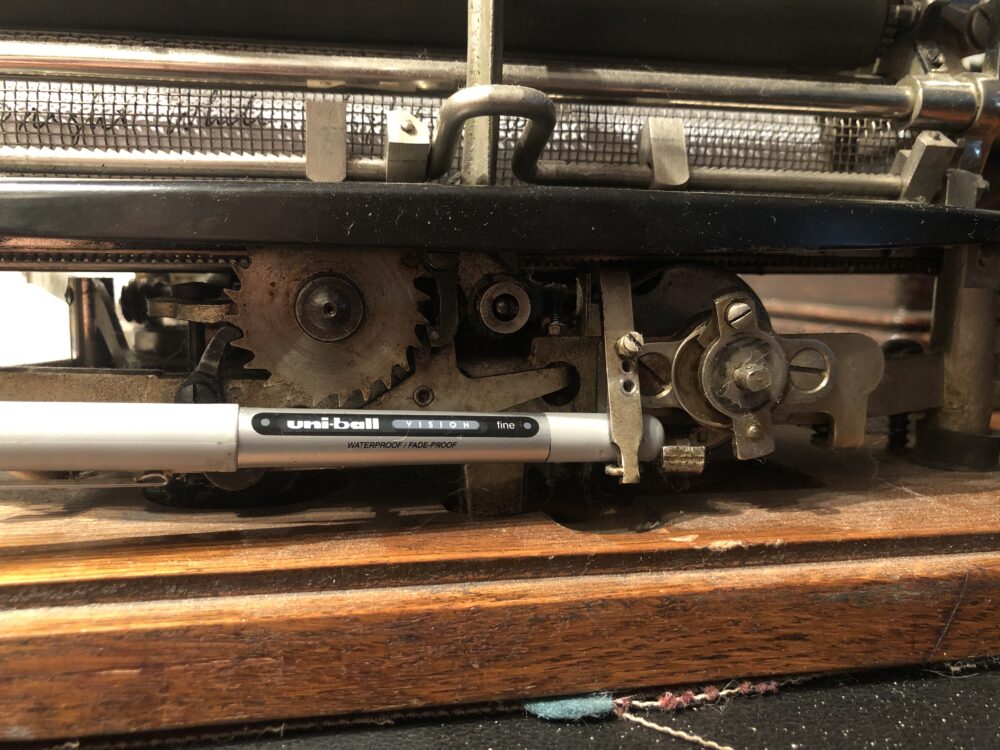

The top of the clamp is attached to a pivot point. In the middle is a screw and at the bottom is a rod attached to a large spring beneath the machine. That spring is attached to the hammer and controls the strength at which it is pulled forward.

By removing the screw and replacing it in a lower hole, more tension is placed on the spring and thus increasing the hammer force.

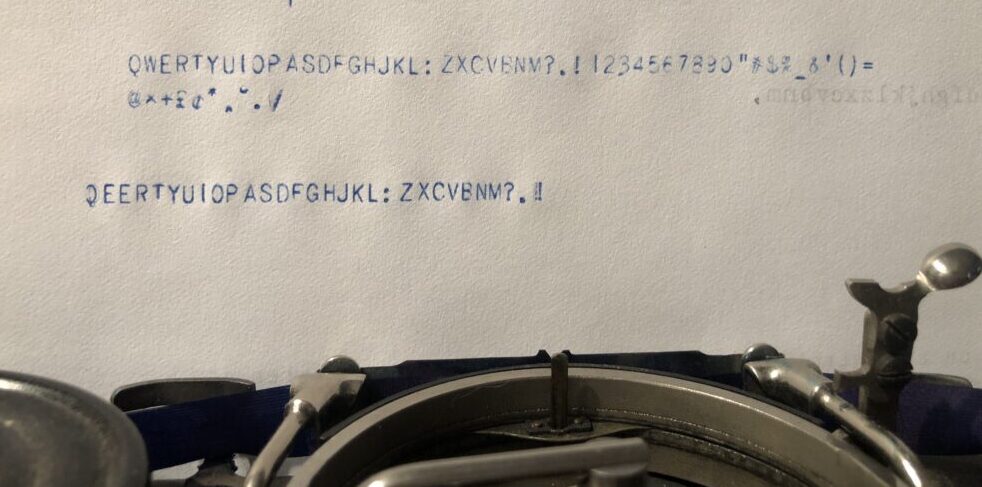

The top line is before moving the screw and the bottom is after. However, if you have moved the screw to the very bottom and the type is still too faint, there is one more thing that can be done but it carries risk.

As demonstrated with this plastic ink pen, a small piece of wood or rubber could be inserted to pull the spring further, but this risks breaking the spring. If the spring breaks the machine can be repaired but will need to be removed from the board, and possible removable of the center section.