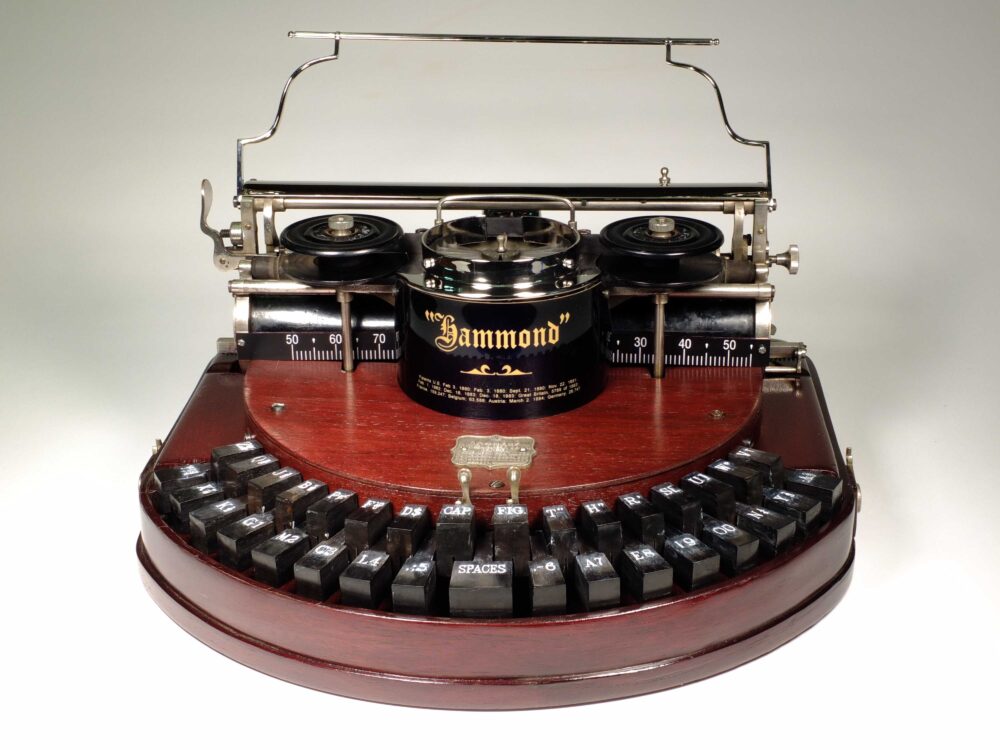

As I was looking closely at an advertisement for the Anvil and Shuttle, I realized I had never blogged about the paper tubes. Obsessed much? Yes. Very much so. This may be the only blog post ever written about Hammond paper tubes, but this obscure and forgotten part is the history of Hammond’s commitment to elegance.

A paper tube is something that screams Hammond regardless of which imitator competitor machine it is found on. Both brilliant and flawed, the paper tube kept the paper inside of the machine until it was needed by the operator. David Herrera makes incredible videos of Hammond’s, and in this he shows the elegance of loading paper into a Hammond.

Paper loading would have presented a bit of a problem when the machine was first conceived. The Sholes and Glidden, and the early Remington’s, and Caligraphs which were first to market a type writing machine, rolled the paper around a giant platen, with the paper held in a wide U shape.

Hammond probably found this to be not only inelegant but the inability to see what you were typing was a major issue for everyone. For Hammond his idea was to house the unused paper within the machine. Thus, the paper tube was born, which meant the paper had to drop into the tube, then rolled downward, without curling or crinkling, and forming into a tube of its own.

The tube was not really a tube at all, but a semi circular tube with a gap of about one inch along the length for the paper. The “tube” was roughly 2 inches in diameter. In this time period a limited number of materials for manufacturing were available. Metal tubing was coming along but these would have been quite heavy and difficult to work with. Certainly inelegant.

Aluminum manufacturing was still in its infancy, not even into production. Bakelite was still 15 years away. Wood might have been interesting, certainly elegant, but surprisingly they didn’t use wood as far as we know. That left celluloid, an “organic plastic” which was the same material used to manufacture the ribbon spools, cowling, and ruler.

For the paper-tube, celluloid solved one problem and created another. The smooth interior of the tube made it a natural fit for the paper to not buckle or crinkle as it was lowered into the machine. It curled into a nice tube, but then it was hard to tell how much paper you had left because the tube obscured it. The other problem with celluloid was its delicacy. It was inflexible and impact would cause it to fracture.

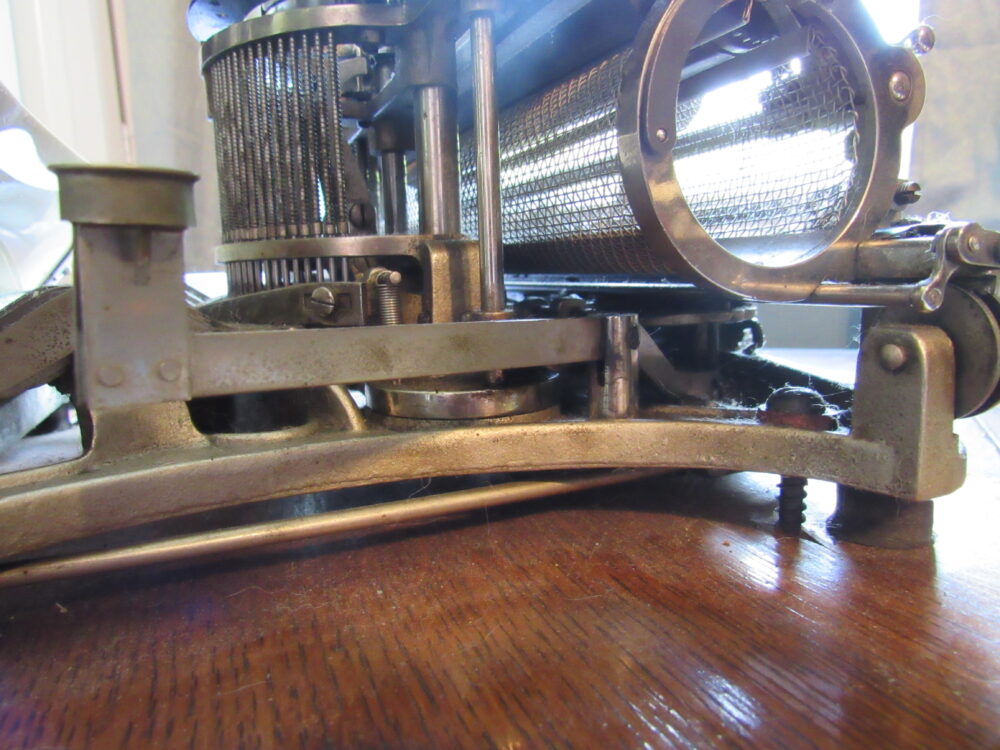

Around 1895 we got an innovation. The perforated metal tube, ostensible made of tin, it could be easily removed from the machine due to its flexibly. It allowed the operator to see how much paper was remaining, and still maintain a level of elegance. Albeit the perforated tube had a tendency to collect dirt.

Finally the company settled on what would become its definitive feature for the next 15 years: the mesh paper tube.

The mesh paper tube was elegant, adding a modern style to the machine that dovetailed perfectly with its center cage. It had the benefit of not getting as dirty as the perforated tube, but also increased the durability. The curved metal plate inside guaranteed a smooth reception for the paper.

The perforated tube, however inelegant, was not defeated and would rise again. The company tried different style designs, such as painting the tube black in later Multiplex’s and Folding Models.

No longer painted black it was a silver tube largely hidden inside the complex, and very heavy, Hammond Electric.

The company got a brief reprieve from the industrial age of the early 1920s when Ralph C. Coxhead purchased the rights, and revolutionized the company into Varityper. One of his early innovations was to ditch the metal tube and use a new synthetic plastic to make a perfectly clear tube. Alas this one has yellowed with age.

Sadly, after the death of Mr. Coxhead on February 6, 1951 the company returned to its industrial roots, both in machine design and of course its paper tube. No longer clear plastic, or modern mesh, it was now an ugly perforated metal tube of aluminum buried inside of an increasingly complex, and heavy machine.