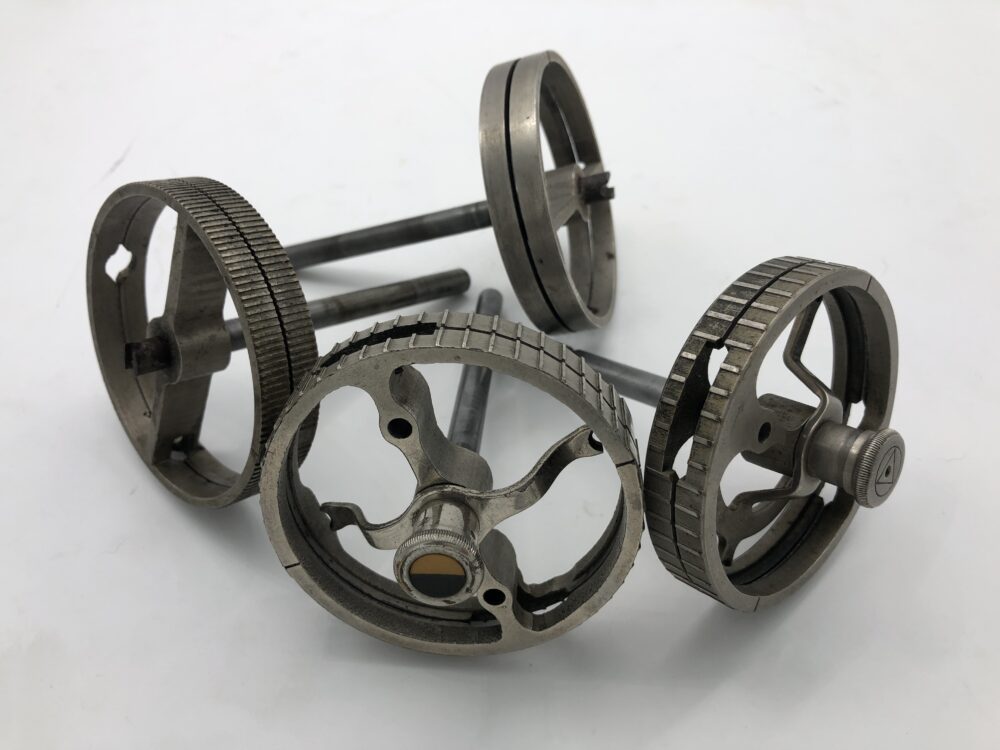

The Anvil is a fundamental part of almost every Hammond ever made. Over the course of one hundred years the anvil can become seized inside the machine. Unfortunately they often look like this…

Removing the Anvil

This is one of the most dangerous repairs of a Hammond because you will need to apply pressure and torque to areas that could snap vital components, ruin the machine, or worse if not done correctly. There is also the possibility that the machine you are working with has been worked on before, for example if the anvil is partially extracted from the machine.

If it’s sitting inside the machine with its shuttle, and type select in tact, this is probably the best starting position you can ask for. To remove it will simply take time and patience, but we can make that a little easier.

Heat is not the answer. The frame is made of cast iron but the shaft is made of low grade steel. Heat might deform this causing permeant damage.

The most vital part is this type select. You must guard this at all costs.

buried in the ground for 100 years before being used as a boat anchor.

As you can see in this irreparable Hammond, the anvil extends down through a shaft into the center of the machine. The center portion is where things break down and the seizing occurs.

Someone attempted to remove this anvil by other means and broke one of the anvil rings. It is quite fragile which brings me to our first rule of anvil removal: Do not use pliers or similar tools!! Hands only.

Loosening things up

You will need to use a penetratingly liquid such as PB Blaster or Kroil Oil, slowly, over the course of days, maybe even weeks, allowing gravity to pull the penetrating agent through the shaft.

Depending where you can reach you will need to liberally apply the penetrating agent daily and just let it sit. After a day, grip the center of the anvil with your fingers and try turning it. If it does not turn, wait longer. If after seven days of penetrating agents, specifically PB Blaster, it still will not rotate with just your fingers then we have to get a little more aggressive.

Getting aggressive…

The shaft itself is not hardened metal and can easily be deformed, permanently destroying the machine. Therefore we must be very, very careful when banging on it with anything. The banging is to create vibrations that open up spaces for the penetrating agent to get through, so only little bit of force is needed.

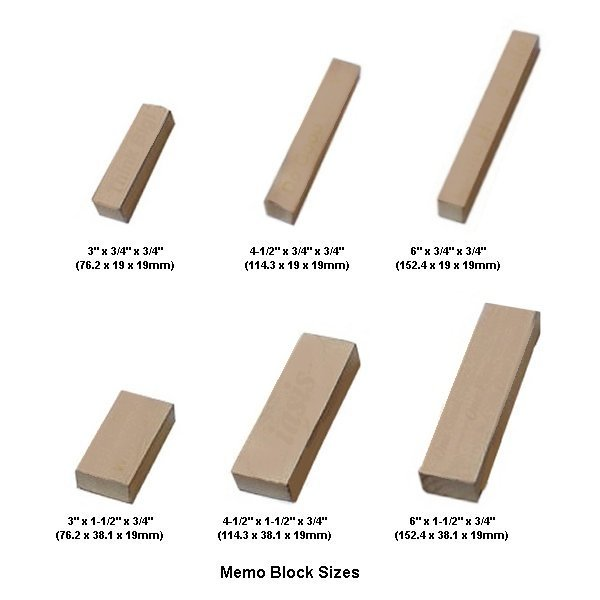

If you are unable to rotate or get any movement out of the anvil after 3 – 5 days of using PB Blaster, you’ll need need a short rectangle of wood that will fit into the machine. Aligning the wood with the lowest point on the shaft, use another block of wood, wooden mallet, rubber mallet, or lastly a metal hammer, and give it a few good taps. Then move up an inch and repeat. Align the wood with the center block and give that a few taps. Don’t try to turn the anvil yet. Give it another 2 days with more penetrating agents, then try turning with your hands again.

The reason for the delicacy is that the metal of the anvil is quite soft and is easy to dent and chip. Once that happens it can be very difficult to ever fully retract it. The wood, being softer, will prevent damage from occurring.

Really aggressive

For this next part you’re going to need a 3/32 or 1/8 pin punch and a metal faced hammer. Take the machine off the wooden board. Fold over a towel or blanket and gently turn the machine over and lay its on its top.

Locate the bottom of the shaft. Apply penetrating agent to this point and wait another day or two. Then using the pin punch, align with the bottom of the anvil shaft and give it a few good taps.

Turn the machine over and try turning it again.

Movement … or not

If you get even the slightest movement, go back to the penetrating agents and start again, and repeat all of the steps. If there is no movement then it is unlikely to move ever again. You can try repeating these steps again, sometimes weeks might be needed.