The Hammond Typewriter Company changed their ribbon spools several times. In the beginning, the company employed the use of a celluloid ring with a hollow center reinforced with a brass collar.

The ribbon attached to the center column by means of a C-shaped metal clip, and a new ribbon was typically purchased loose and affixed to the cylinders. The cost of a replacement pair was $1 in 1895, about $32.62 today.

These spools were not Bakelite, that would not be invented until 1907 by Leo Bakeland, in Yonkers. Instead, the first spools were made from celluloid. Developed in the late 19th century by John Wesley Hyatt, in response to an advertisement for a replacement for ivory billiard balls, it was really the first man-made plastic.

You can read about the fascinating history of celluloid here, but suffice to say it had a few things going for it, and a few against. Celluloid was easily moldable into practically any shape. Flexible, cheap, and waterproof, it was first invented as a replacement for rubber, but due to its drawbacks remained a medium for smaller items such as dominos, checkers, and typewriter spools.

Celluloid is actually quite brittle, and for Hammond celluloid, it should be handled as little as possible. It can shatter if dropped or squeezed, spontaneously rupture, discolour, and warp if it gets too hot.

This is most noticeable in the celluloid fingerboards, which will bow out, typically due to long term hot and cold swings in temperature. Celluloid is also flammable and should not be near an open flame. Some might say its flammable, or explosive nature, was a major impediment to its wider use.

Photos courtesy of The AntiKey Chop

The celluloid spools lasted until after Hammond’s death in 1913, when the company migrated to metal spools.

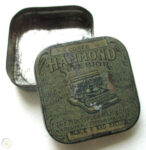

Around 1916 the company would get rid of the spool altogether and replace it with a ribbon cup. Not as elegant as the celluloid spools, messier, but cheaper. Customers would purchase a tin of ribbon that was wrapped in foil.

The cups were topped with metal caps which gave the machine a more industrial look, several steps removed from its original elegance. The cups have a center post that fits around the rubber cylinder at the center of the ribbon spool.