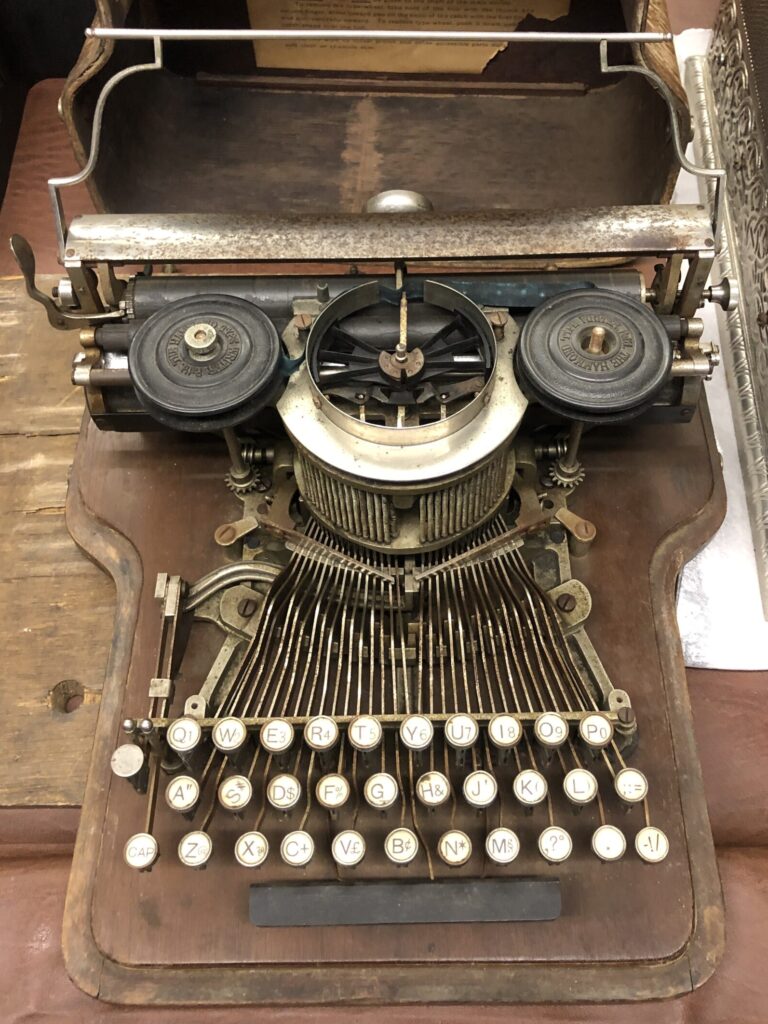

I was eating a ham-and-cheese sandwich today gazing at some Hammond’s when I noticed something interesting about two of them. The first is from around 1887-1890 with a serial number in the 12,000 range, and the second is from the 18,000 serial era. There are quite a few differences, can you spot them all?

If you said it was the paper tube you’re correct on that one, but that’s easy. Hammond’s began with solid paper tubes, then perforated metal tubes, finally a mesh tube.

Keys are different. Glass top versus celluloid…

Harder because of the angle is the ruler. The earlier Hammond has a celluloid ruler, whereas the later has a metal rod etched with measurements.

The wooden board is shaped differently..

How about that frame?

The differences in the width of the frames was so subtle it surprised me. A Hammond No. 1 universal with a serial number less than 14,000 (about) will have a narrower frame. Compared to a No. 1 universal with a serial number around 18,000, the mid-to-back part of the frame is wider.

Notice the spacing and size of the keys. The earlier model had smaller keys with glass. The wider frame uses the celluloid keys. However, it is the placement of the figure/caps key that caught my attention.

With earlier No. 1 universals the distance between CAP and Z is quite narrow, whereas in the 18,000 era it’s about the width of a finger. Widening the frame required a slightly longer Fig/Cap arm, thus creating the space.

We know that the first company to produce Hammond’s in large numbers was the Garvin Machine Company, before Hammond began manufacturing on their own. Records tell us that a machine with the serial number 3,150 was made in 1887.

Then in 1890 we have the Clough machine that was gifted by Hammond to Jefferson Moody Clough, serial number 14,421.

About that Clough machine, though….

That one has the glass keytops, both celluloid and metal ruler, almost a mix and match. It appears the larger frame was kept and optional class keytops could be added, or celluloid, but we’re also back to the solid paper tube.

With serials of 3,150 and 14,421 we can narrow that down to 1887 – 1890. That was about 11,000 machines! Enlarging the frame was a major design change because now everything had to be made to fit the new frames. For example, the replaceable keybeds that held each keybar at the right height, and pivot angle. That had to be narrowed.

The bracket for the upper part of the machine that held the beautiful type-pin cage had to be widened; longer keybar retainer, basically half the machine needed an adjustment.

Food for Thought

Serial numbers can be inaccurate and often there is no rhyme or reason to them, so take this with a grain of salt… According to some really old reports by the U.S. Senate, in 1890 the average number of working hours for manufacturing in a major city was 60 hours per week.

For talking purposes let’s say there were 270 working days in the year 1890; likely more.. That would mean the factory was producing roughly 40 machines per day, or about 3 machines per hour, between 1887 and 1890.

Questions to explore:

- Were those produced by Garvin, or in house?

- What were numbers like during full scale, in house production?

- Did the frame redesign slow production?

- What other benefits and challenges did widening the frame add?

- Was there a change in the keybar length?

- Other nerdy measurements abound such as the placement of the mainspring!

Time and research will tell….